The MVE Pneumatic Desoldering Module is indispensable for a complete desoldering process. Clean and dry compressed air is required.

It provides the best soldering quality thanks to JBC Most Efficient Soldering System and additionally Sleep & Hibernation modes help to extend life of tips.

It features all the Excellence range benefits such as station customization, full control of soldering processes and remote work management.

Although the Control Unit is compatible with 10 different JBC tools, the DMPSE works simultaneously with the T210 Precision Purpose Handle, the T245 General Purpose Handle, the AM120 Micro Tweezers and the DR560 Desoldering Iron.

REFERENCES

DMPVE-9QA

100 V

DMPVE-1QA

120 V

DMPVE-2QA

230 V

PRODUCT COMPOSITION

- 1

DME 4 Tools Control Unit

- 1

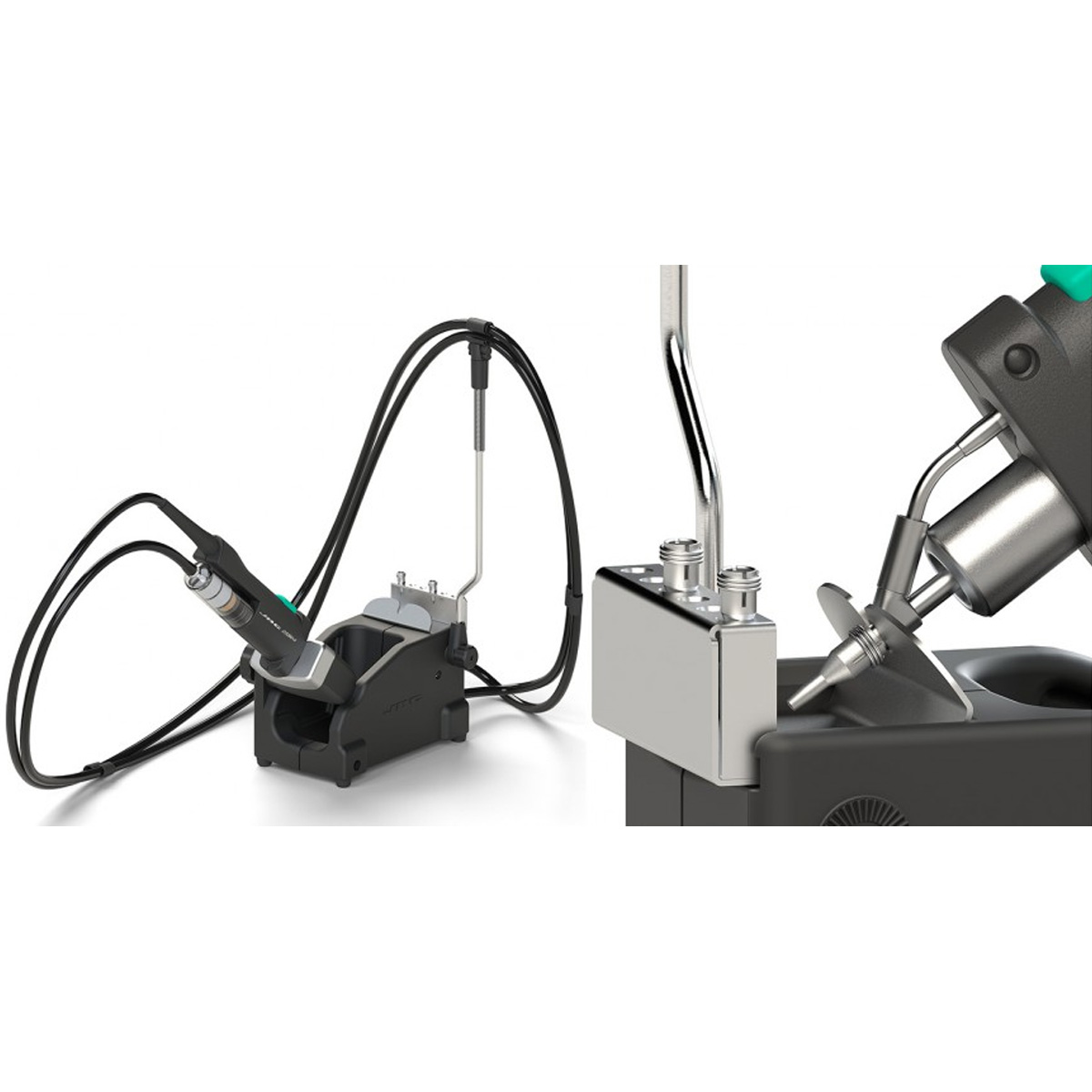

MVE-A Pneumatic Desoldering Module for DDE & DME

- 1

AM120-A Adjustable Micro Tweezers

(cartridge not included)

- 1

T210-A Precision Purpose Handle

(cartridge not included)

- 1

T245-A General Purpose Handle

(cartridge not included)

- 1

DR560-A Desoldering Iron

- 2

AD-SE Stand for T210 & T245 Handles

- 1

AM-SA Stand for AM120 Micro Tweezers

- 1

DR-SE Stand for DR560

- 1

SCH-A Cartridge Holder

- 1

CL8499 Manual Tip Cleaner

SPECIFICATIONS DMPVE-Q STATION

Selectable Temperature

90 to 450 ºC / 190 to 840 ºF

Vacuum (at 6 bar)

90% / 680 mmHg / 26.8 inHg

Flow rate (at 6 bar)

15 SLPM

Air pressure supply

up to 6 bar

USB-B (rear)

Software PC / Traceability

USB-A (front)

Firmware update.

Soldering Graphics / Profiles management.

Dino-Lite USB microscope connection. Compatible models: AM2011 and AM2111.

Robot

RS-232 remote control or Smart Fume Extractor connection

LAN

Remote control / Traceability

Equipotential bonding

Optional connection to EPA

Tip to ground resistance

Peak power

160 W per tool – 23.5 V

Reviews

There are yet no reviews for this product.